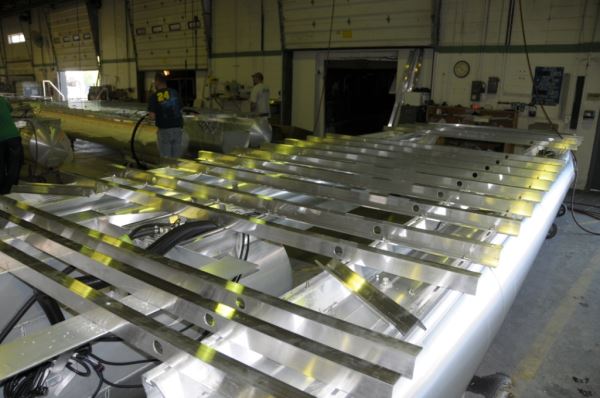

In part one of “What Lies Beneath”, we took a look at how the process and materials for making strong, durable and long-lasting pontoon logs and cross members came together. We learned that in some of the basic models, cross members were spread evenly throughout the vessel, while in performance models, stronger members were implemented and spaced closer together by comparison. Pontoon logs come in all different shapes and sizes, and while some may be chambered and baffled, others are foam-filled. While some pontoons are round, others utilize a U-shape construction. For the second portion of “What Lies Beneath”, we'll explore some of the construction methods of the hull, seating, bulkheads and other aspects of manufacturing that go into making the pontoon boat.

More and more pontoon companies have begun to utilize heavy gauge aluminum during the construction process, due to its long-lasting composition, resistance to corrosion and flexibility under stress. On a Premier pontoon, aluminum can be found through much of the vessel. The rails are constructed using 1-1/4-inch anodized .090-gauge aluminum and built with an integrated slot for the panels, which are then pressure pinched into the rail slot. Curved railings are bent using proprietary methods, but each weld done on the rails is done so prior to a powder coating process, which further extends the life of the material.

More and more pontoon companies have begun to utilize heavy gauge aluminum during the construction process, due to its long-lasting composition, resistance to corrosion and flexibility under stress. On a Premier pontoon, aluminum can be found through much of the vessel. The rails are constructed using 1-1/4-inch anodized .090-gauge aluminum and built with an integrated slot for the panels, which are then pressure pinched into the rail slot. Curved railings are bent using proprietary methods, but each weld done on the rails is done so prior to a powder coating process, which further extends the life of the material.

Another point stressed in the Premier construction process is that no wood is used in the furniture. Although wood is buoyant and durable, it doesn't take long for water to seep through, warping and rotting any wooden materials used aboard. To further help dispel water from the boat, Premier has constructed an integrated drainage system to keep water from pooling and becoming stagnant.

While the boat is under construction, the wiring for all of the various components has to be installed. For that, Premier introduces fully braided wiring harnesses that are protected with a fire-retardant protective loom throughout the 'toon. Each wire is made of marine-grade material, and extra wiring is set in place, should the owner desire to install future electronic upgrades.

While the boat is under construction, the wiring for all of the various components has to be installed. For that, Premier introduces fully braided wiring harnesses that are protected with a fire-retardant protective loom throughout the 'toon. Each wire is made of marine-grade material, and extra wiring is set in place, should the owner desire to install future electronic upgrades.

While these construction methods answer some of the issues associated with water damage and corrosion, Avalon Pontoons has created something that answers the issue of fuel-fill splash back. Through years of asking for a way to ease fueling and get rid of that fuel splash back, Avalon created a carbon canister flow-through gas fill. This design has rectified the issues associated with slow fueling and aids in automatic fuel shutoff by easing pressure out of the tank while fueling. While this may not sound like a tremendous hassle, many boaters would agree that a boat meant for ease of use and comfort should be as simple as possible.

Like Premier, Avalon has also come to the understanding that integrating drain ports aboard the boat is essential to keeping the upholstery tidy and clean. While the materials used onboard are marine-grade, standing water can leave unsightly stains and weaken the integrity of the material over time. Avalon also encourages strength and rigidity in its construction and therefore welds each wall joint on all for sides, ensuring the strength of each weld four-fold. To add to the strength and longevity of each of its boats, Avalon also integrates aluminum frame seating. While other companies use Rotocast framing for its seats, Avalon believes that aluminum construction throughout the entirety of the vessel provides improved strength, and backs that construction with a lifetime warranty to prove its trust in it.

A lot of forethought goes into the construction process. With all of the technological advancements possible for a pontoon and all of the money invested into it, manufacturers have stepped up their game to ensure that owners are given the best possible care and the best possible boat. When it comes time to install the electronics themselves, these companies feel that these systems should also reflect the amount of forethought and reliability that they put into the vessels construction.

A lot of forethought goes into the construction process. With all of the technological advancements possible for a pontoon and all of the money invested into it, manufacturers have stepped up their game to ensure that owners are given the best possible care and the best possible boat. When it comes time to install the electronics themselves, these companies feel that these systems should also reflect the amount of forethought and reliability that they put into the vessels construction.

JC integrates a Clarion waterproof AM/FM/CD player into each of its pontoon models to ensure that in any type of weather, the entire sound system is protected from the elements. To further improve their protection, JC has also implemented an aluminum bottom skin, which can be found on each of its three-tubed models. Also, all of the fittings and fasteners on JC's pontoons are stainless steel, which provides superior strength and corrosion resistance for years to come.

Every rail found onboard is powder coated to further reinforce the durability of its construction, so if there were any concerns about the boat’s integrity, those concerns can be laid to rest.

Every rail found onboard is powder coated to further reinforce the durability of its construction, so if there were any concerns about the boat’s integrity, those concerns can be laid to rest.

It's clear that throughout the years, pontoon manufacturers have stayed vigilant when constructing each pontoon. Whether you're a beginner looking for a standard model, or an avid boater looking for one of the top-of-the-line configurations, each boat has been painstakingly designed to provide the best in maritime construction.

Through trial and discovery, these great pontoon manufacturers have gathered the know-how and intuition to create pontoon boats that last for years and mitigate issues before they even arise. The pontoon boats they craft are above reproach and have been designed to answer needs and desires for owners before they even know they have them. There are many great companies that have come a long way in technological advancements to give consumers the best in boating life. Through their clever and ingenious methods of construction, their boat has answered questions of reliability and longevity, as well as capability and comfort. Construction methods have been changed and altered as the need for stronger, faster boats has become more prevalent. While some of the original methods of construction are still the baseline for the way a pontoon is crafted, many practices have molded and conformed to the increasing demand for better versatility and power. In the future, these great companies will undoubtedly develop more revolutionary construction methods that will lead to even better opportunities for boat owners. The one thing to keep in mind is that, rest assured, if you find yourself in one of these great pontoons, you'll find yourself with peace of mind on the water, and a great day of fun in the sun.

“What Lies Beneath” is a three-part series on the building and construction process in the pontoon industry. Part three tomorrow will focus on furniture and the finishing touches.