When you spend a lot of time on the water, you start to notice some of the things that the new guys never see. To the untrained eye, pontoon boats look only superficially different. Sure, they're rectangular in shape, utilize pontoon logs for flotation, house an outboard engine at the aft and are often misidentified as slow floating party barges. To the salty pontoon captains among the lot, you know that there's more diversity in ’toons than contours in the human fingerprint. Taking a closer look at a pontoon boat reveals a complex world of engineering genius, years of refining and redefining what a pontoon is capable of. To understand the diversity in the world on pontooning, all you have to do is pull back the top layer and find what lies beneath.

In this industry, different companies utilize different construction methods when creating a pontoon design that is signature to them. While some companies use traditional methods, others try to expand on those methods, or take a different avenue and engineer a completely unique design.

In this industry, different companies utilize different construction methods when creating a pontoon design that is signature to them. While some companies use traditional methods, others try to expand on those methods, or take a different avenue and engineer a completely unique design.

Nautic Global Group govern different lines of pontoons that have helped revolutionize the industry. For each line, including Sweetwater, Sanpan, Parti Kraft and Aqua Patio, NGG uses the same round log construction. Round logs are traditional on pontoon boats and have been proven reliable throughout the years. Many people have found them more than adequate and round logs are often preferred over different configurations. Each log is baffled, which seals up sections within the log (usually two or three sections) and is fitted with nosecones that are specially tooled to line up with the diameter of the round log.

Mike Farmer, the pontoon project engineer at NGG, shared his insight on their log manufacturing methods.

“We choose to use the traditional round shape logs to increase precision and quality,” says Farmer. “Baffling sections of the tube keep the log from filling with water in the event of a puncture. We used this method to give owners extra safety, as well as give them a great comfortable ride at a more affordable price line.”

“We choose to use the traditional round shape logs to increase precision and quality,” says Farmer. “Baffling sections of the tube keep the log from filling with water in the event of a puncture. We used this method to give owners extra safety, as well as give them a great comfortable ride at a more affordable price line.”

For owners searching for more performance in their handling and banking, every line that Nautic Global owns offers lifting strakes, which drastically change the way that the boat operates in the water.

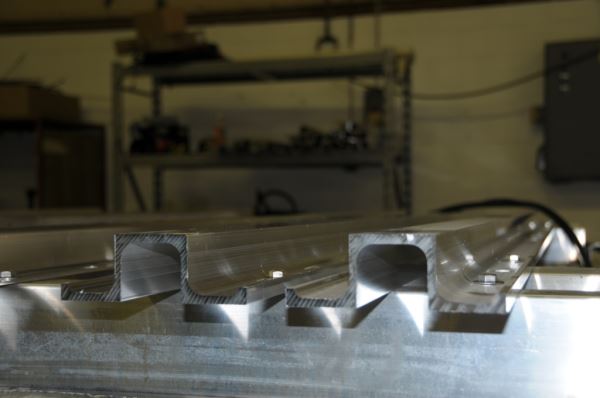

In the next step of construction the cross members are installed. There are different methods, as well as different models of cross members that are used during this phase of the construction. Nautic Global uses 3-inch tall C-channels in all of its Sweetwater models. In the regular Sweetwater line, each C-channel is spaced in regular 24-inch intervals, with a heavy-duty 1/4-inch C-channel placed at every deck seam, which is at every 48 inches of the boat. On the premium line of Sweetwater, each cross member is placed at regular 16-inch intervals and with the bow deck being curved on these models, a special channel weld is used to support the distinct curvature of the bow area.

For Aqua Patio and Sanpan pontoons, NGG uses the same method as used on the Sweetwater premium line, but with an added welded channel structure located at the aft end of the boat, which allows for rear extension platforms on either side of the motor well area. Farmer explained the reason for these different construction methods.

For Aqua Patio and Sanpan pontoons, NGG uses the same method as used on the Sweetwater premium line, but with an added welded channel structure located at the aft end of the boat, which allows for rear extension platforms on either side of the motor well area. Farmer explained the reason for these different construction methods.

“The Sweetwater Premium, Aqua Patio and Sanpan lines provide higher passenger and motor capacities, as well as offer more options and standard features than the base models do,” says the pontoon project engineer. “These added features add increased weight to the boat and allow owners to install larger, heavier engines. All of these variables are taken into consideration when deciding which lines will have the more robust structure with 16-inch spacing as opposed to 24-inch spacing.”

Nautic Global Group has found a method that works so well that every line of pontoon they offer is constructed using the same fine-tuned style, but there's more than one way to make an amazing product.

PlayCraft’s Joe Dorris explains why for the last 40 years, they've taken a slightly different approach to making the perfect pontoon.

“Our PlayCraft line has used U-shaped pontoon logs for the last 40 years,” says Dorris. “There are a lot of reasons to take the U-shaped route, but one of the main reasons is safety. The U-shaped logs are filled with foam, which keeps the aluminum from buckling under stress and filling with water, should a puncture occur.”

“Our PlayCraft line has used U-shaped pontoon logs for the last 40 years,” says Dorris. “There are a lot of reasons to take the U-shaped route, but one of the main reasons is safety. The U-shaped logs are filled with foam, which keeps the aluminum from buckling under stress and filling with water, should a puncture occur.”

Dorris's method of constructing a U-shaped log for PlayCraft is based off out-of-the-box thinking that also paid off in practical ways. The U-shape allows the pontoon to move smoothly in the water, but its unique construction also allows each log to be filled with foam, which greatly raises the overall safety of the boat and gives boaters that peace of mind that makes for a great day on the water.

Although PlayCraft contrasts from Aqua Patio, Sanpan and Sweetwater, PlayCraft’s other line, Hampton, does utilize the traditional round shape log during construction. Many people prefer the traditional round shape and Dorris uses this method to offer owners exactly what they want. Hampton's logs are baffled in each section and the log is pressurized.

After the logs are ready for installation, it comes down to the cross members. On all of the PlayCraft line, each heavy-duty C-channel cross member is spaced at 16-inch intervals, while Hampton pontoons run cross members at 16 inches for the majority of the length of the boat and 24-inch centers for the remaining third of the length. Both PlayCraft and Hampton pontoons use a one-piece plywood deck, so there are no sections on either boat that need to be reinforced. To keep the stresses of heavy engine installation under control, more cross members are located at the aft of the boat and both boats use 18 cross members total, on average.

After the logs are ready for installation, it comes down to the cross members. On all of the PlayCraft line, each heavy-duty C-channel cross member is spaced at 16-inch intervals, while Hampton pontoons run cross members at 16 inches for the majority of the length of the boat and 24-inch centers for the remaining third of the length. Both PlayCraft and Hampton pontoons use a one-piece plywood deck, so there are no sections on either boat that need to be reinforced. To keep the stresses of heavy engine installation under control, more cross members are located at the aft of the boat and both boats use 18 cross members total, on average.

Another important fact to note is that both PlayCraft and NGG fabricate their pontoon logs in-house. The PlayCraft line of pontoons use 5000- to 6000-pound aluminum coils, which are then cut, bent and formed at the PlayCraft factory, while Hampton pontoon logs are precut flat sheet sections, which are also formed at Hampton's factory. The same is true for Nautic Global, with all of its logs being fabricated in-house using their own unique methods of construction.

Another important fact to note is that both PlayCraft and NGG fabricate their pontoon logs in-house. The PlayCraft line of pontoons use 5000- to 6000-pound aluminum coils, which are then cut, bent and formed at the PlayCraft factory, while Hampton pontoon logs are precut flat sheet sections, which are also formed at Hampton's factory. The same is true for Nautic Global, with all of its logs being fabricated in-house using their own unique methods of construction.

Throughout the industry, companies take different approaches to making a distinct and unique pontooning experience. Although these methods may contrast greatly, the end result is still the same. These are just a few of the companies that help make the industry great. In the next portion of this feature, a more detailed look at some of the common and unique construction practices will be examined to help paint a greater picture of what really lies beneath.

Champagne Metals

Champagne Metals, who supplies the aluminum to many of the pontoon manufacturers in the Midwest, recently built a new 85,000-square-foot processing and distribution center in Middlebury, Ind. The aluminum service center buys aluminum from mills, cuts it and then sells it directly to the manufacturers. The investment in the new building and equipment is more than $5 million according to Mike Champagne, president and CEO of the company based in the Tulsa, Okla.-area.

“We are involved in every aspect of it in this market,” says Champagne. “That’s why we decided to come to this part of the country. We could have gone to Detroit or Chicago, but we think there’s more aluminum bought in Elkhart County than any county in North America, so why would we not come here?”

The new equipment in Middlebury can cut sheets that are up to 80 inches wide and one-quarter-inch thick.

“There’s no equipment with our capabilities in this part of the country,” adds Champagne. “We are cutting aluminum right in the backyard of several local pontoon companies and we’re hoping to take people’s inventory down.”

What Lies Beneath is a three-part series on the building and construction process in the pontoon industry. Part two tomorrow will focus on the assembly process.