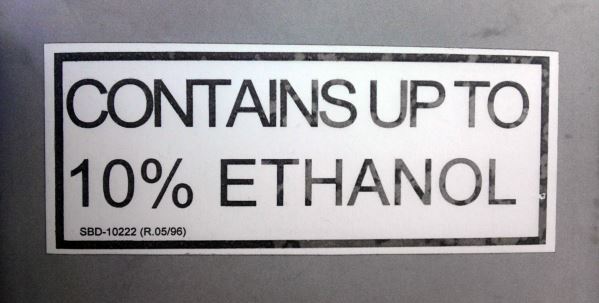

Unless you have been boating using a canoe or kayak the past decade, you may not be aware of a corn distilled product called E10. Due to government mandates (forceful use of the product), it must be distributed at the rate of 10% ethanol (E10) mixed into all gasoline fuels sold in the United States & soon this may be raised to 15% (E15).

I won’t be discussing all the problems of E10’s scores of fact-based negative issues in this DIY but if you are a boater and use a gasoline engine (older or new) I’m sure that you are well aware of E10’s severe drawbacks when used in Marine fuel tanks to supply fuel to outboard, inboard, and I/O engines.

One problem with E10 added to gasoline is moisture, water, H2O, because Ethanol E10 absorbs water like a sponge. Moisture from its surroundings, air, condensation and storage practices where it is purchased all contribute to engine problems, hard starting, stalling at both high and low speeds, misfiring, or just refusing to run or start at all. If you add phase separation to the long list of E10‘s multitude of drawbacks, it's just one more consideration when you are 40 nautical miles from shore in the middle of one of the Great Lakes.

The first line of attack one usually takes is to add one of a wide variety of “snake oil additives” which I find actually multiplies the problems as most all contain Ethanol, creating a worse problem when added to the already E10-modified fuel. I have spent countless hours reading and testing a variety of assorted additives and have concluded there is no apparent cure for water saturation problems as well as phase separation (E10 degrades within days of being stored) other than fresh gas before every cruise. Next, one can install a fuel-water separator. What it does is what the name suggests: filter water from the fuel that is held in suspension from the E10 being added to the fuel. The smaller fuel filters that are OEM-installed and were adequate in the pre-ethanol days sometimes are unable to do a thorough job of removing water particles and insufficiently sized to handle water absorption from E10. Fuel-water separators today have to be designed to stop 99.9% of the water passing through. 10 Microns should do the process as fuel is drawn up from the bottom of the gas tank where most water lays before it enters, either in a quad-jet carburetor as in our 33-season project boat, or in yours if it’s one of the newer computer-controlled injected 4-cycle motors, an I/O, or an oil-injected 2 cycle.

For More PDB Features, Exclusives, and News, Subscribe today!

Most fuel-water separators are sold as 2 parts, a cast head bracket to bolt to a bilge bulkhead near the gas tank and a spin-on filter. The separator basically removes water from E10 before it enters the engines fuel distribution system.

The filter mounting casting (fuel lines and filter attach into this) are available with different sized in-and-out threaded ports ready to receive a barbed fitting for the size hose you need. Be aware that if below deck you CANNOT use the clear plastic manual drain bowl feature (to draw off contained water) and only the metal type. If a fuel-water separator will be visible ABOVE DECK the clear plastic drain bowl type is permissible by USCG regs. Use only USCG-approved steel-braided fire-resistant fuel line for your conversion along with double stainless clamps over each hose/barb fitting or other fuel fittings. Attach the filter head plate casting with hex-head-threaded screws as per photos and attach GPH (gal per hour) or GPS senders to the OUT port of the base assembly (if used) at this time from there into the engine.

As you fit each appropriately threaded sized barb fitting into the filter base assembly and new fuel hoses, obtain a container of PERMATX brand Item #80017 AVIATION FORM-A-GASKET liquid sealant. ”Accept no substitutes,” as the old saying goes, since this is the only sealant that I have found so far that is not affected by the corrosive and solvency effects of E10 ethanol. While doing any work near the fuel tank and lines, do take all safety measures. Take extra time to inspect fuel gauge attachment/sender access plate gaskets as most all will be found to have seepage due to ethanol fuels. Remove and reseal with #80017.

For this DIY I have selected the RACOR 32R-Rac-02 (includes cast head, filter can assembly and drain bowl) due to its easy mounting, 3 barb/fitting selections and the additional manual water drain plug. I suggest before each outing to carefully drain the bowl of water into an appropriate container. If choosing another brand, allow for differences in installation and features.

Safe boating and dry fuel.